By NASI HAKO

Two Makhanda residents are making life-saving equipment for health and essential services workers in the frontline of battle against the Covid-19 pandemic. They’re doing it out of their own pocket, with nothing but a talent for innovation, a wish to help, and a small array of 3D printers.

In normal times, Christian Carver manages the African Musical Instrument factory. Earl Prinsloo is Associate Professor of the Rhodes University Biotechnology Innovation Centre (RUBIC).

As the pandemic began to spread, it became clear that a province-wide shortage of personal protective equipment (PPE) was putting health and other essential services workers in danger.

Carver is wired to help, as well as to “make a plan”. He’s part of the ‘maker’s movement’ – people who teach themselves and others useful skills and techniques and then apply them to solve practical problems.

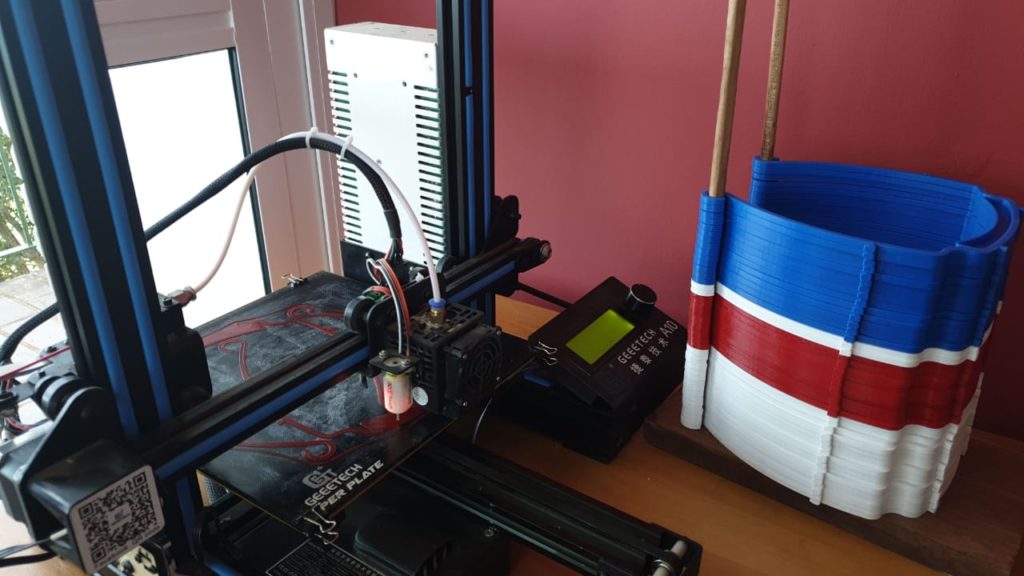

He reached out to Prinsloo to ask if he could use his 3D printers. RUBIC focuses on the uses of 3D printing in biotechnology in tissue engineering and in developing low-cost solutions for scientific problems. Prinsloo happily obliged and donated materials plus the use of the printers.

At the time Grocott’s Mail interviewed him last week, Prinsloo confirmed that he had delivered 72 face shields, for local healthcare workers including doctors, clinic staff and hospital workers.

The materials for the shield are what Carver described as ‘basic and easy to find’. He pays for them out of his own pocket. It takes an hour to finish printing.

Face shields serve as a life-saving device for essential workers, as they create a clear, breathable barrier between individuals, preventing the virus from being spread when speaking. It covers more of the face than a regular face mask.

Carver says he has even started supplying certain stores with the face shields; however, he only asks to be paid enough to cover his expenses. He says his priority is the safety of his fellow community members more than earning an additional income.

The protective gear has reportedly been received well by the community and the pair are determined to continue producing the life-saving device for frontline workers who risk their safety daily for their communities, and for the many who can’t afford to buy PPE themselves.